The global demand for high-quality fish meal continues to rise, driven by its essential role in aquaculture, animal feed, and agriculture. Investing in a turnkey fish meal plant ensures a streamlined, cost-effective production process—from raw material handling to final packaging. This article explores the key components, benefits, and operational efficiency of a modern fish meal processing plant, helping businesses maximize output while maintaining sustainability.

Why Choose a Turnkey Fish Meal Plant?

A turnkey fish meal production line offers a complete, ready-to-operate solution, minimizing setup delays and technical challenges. Key advantages include:

- End-to-End Automation – Advanced fish meal processing equipment reduces labor costs and improves consistency.

- High Yield & Low Waste – Efficient cooking, pressing, drying, and grinding systems extract maximum protein content.

- Compliance & Sustainability – Modern plants adhere to environmental regulations, reducing odor and water pollution.

Core Components of a Fish Meal Manufacturing Plant

A well-designed turnkey fish meal factory integrates several critical stages:

- Raw Material Reception – Fresh or frozen fish is unloaded, sorted, and prepared for processing.

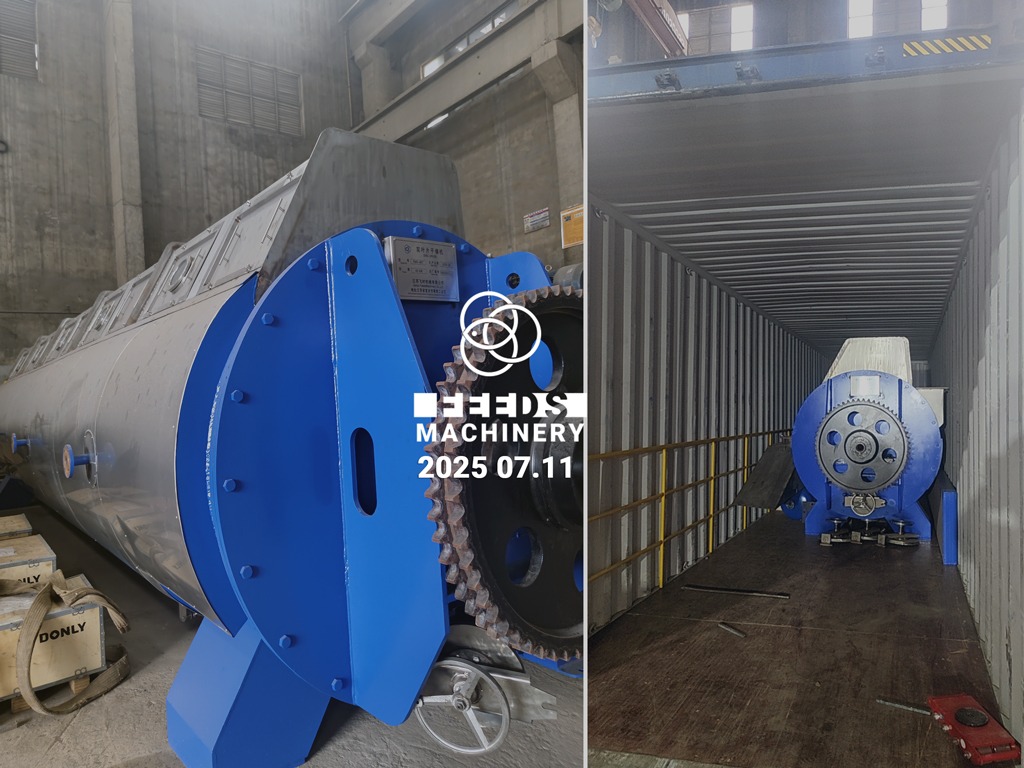

- Cooking & Pressing – Steam cookers and screw presses separate liquids (fish oil) from solids (press cake).

- Drying & Grinding – The press cake is dried and milled into fine fish meal powder, ensuring long shelf life.

- Oil Extraction & Refining – Recovered fish oil is refined for use in feed or industrial applications.

- Packaging & Storage – Automated bagging systems ensure hygienic, dust-free packaging.

Key Considerations for Setting Up a Fish Meal Plant

- Capacity Planning – Choose between small-scale fish meal plants (5-20 tons/day) or industrial fish meal production lines (50-500 tons/day).

- Energy Efficiency – Opt for plants with heat recovery systems to reduce fuel consumption.

- Regulatory Compliance – Ensure wastewater treatment and emission controls meet local standards.

Long-Term Benefits of a Modern Fish Meal Processing System

Investing in a fully automated fish meal plant enhances profitability through:

- Higher Product Quality – Consistent protein content (60-72%) meets premium market demands.

- Reduced Operational Costs – Energy-efficient drying and automated controls lower expenses.

- Scalability – Modular designs allow future expansion as demand grows.

Conclusion

A turnkey fish meal processing plant provides a hassle-free, high-efficiency solution for producers aiming to meet global demand sustainably. By integrating advanced fish meal machinery and eco-friendly practices, businesses can achieve superior product quality while optimizing costs.

Interested in a customized fish meal production solution? Contact us today for a tailored turnkey project proposal based on your raw material and output requirements!