What is a disc dryer?

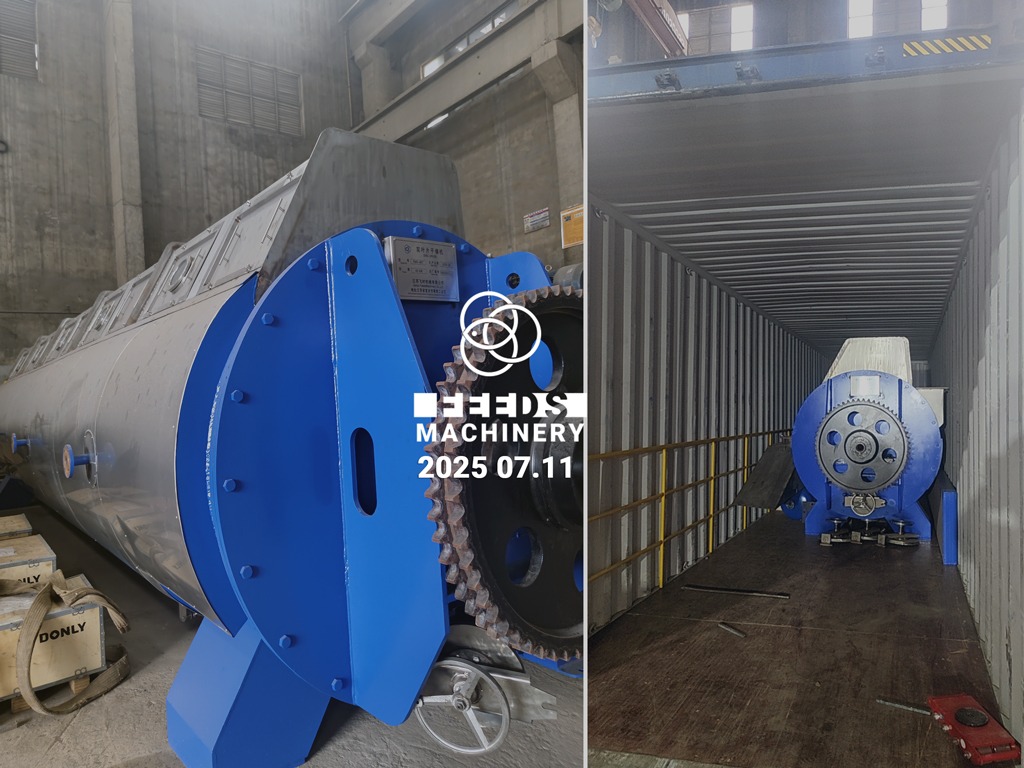

The Disc Dryer is a cornerstone technology in modern, energy-efficient fish meal plants, renowned for its gentle yet highly effective indirect drying of protein-rich materials like fish slurry and press cake.

It utilizes rotating discs to distribute heat evenly across the material, ensuring efficient moisture removal.

Seamless steel tube spindle

Adopt seamless steel tube to avoid the risk of spindle breakage

Hidden Seam Design

Reduce the wear of discs and materials and prolong the service life

Stainless Steel Bezel

Prevent the material from slipping in the blade and improve the drying efficiency for fish meal

What a disc dryer can do?

Disc Dryer is designed to perform several key functions:

Drying: Efficiently removes moisture from materials to produce a stable, dry product.

Heat Recovery: Utilizes advanced heat recovery systems to reuse waste heat, improving energy efficiency.

Consistent Output: Ensures uniform drying and consistent product quality.

Environmental Protection: Reduces emissions and environmental impact through efficient drying and advanced filtration systems.

How a disc dryer works?

In fish meal processing, the wet feed (fish slurry or press cake) is evenly distributed onto the top heated disc.

As the material travels over the series of slowly rotating discs heated internally by steam, moisture is gently evaporated through indirect contact.

The adjustable disc rotation speed and staged heating zones allow precise control over drying time and temperature profile, crucial for preserving protein quality and preventing overheating/scorching in sensitive fish material. The dried product is discharged from the bottom disc.

Model

| Model | Disc Diameter | Size(mm) | Motor Power(Kw) | Heating Area(m2) | Capacity(Mt/24h) |

|---|---|---|---|---|---|

| FMD-50 | 1200 | 7600X2000X2850 | 37 | 96 | 50 |

| FMD-80 | 1450 | 8300X2500X3100 | 45 | 158 | 80 |

| FMD-100 | 1450 | 10000X2500X3100 | 55 | 198 | 100 |

| FMD-150 | 1700 | 11200X2500X3200 | 75 | 261 | 150 |

| FMD-200 | 1950 | 11800x3000x3500 | 110 | 350 | 200 |