How does fish meal and oil are produced

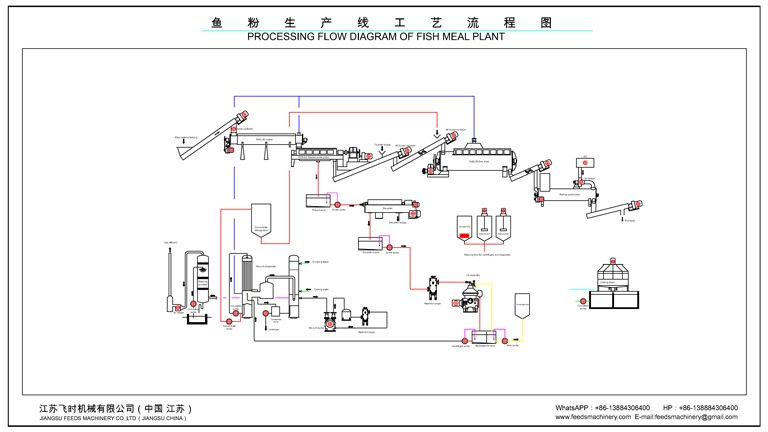

The fish meal plant production line typically includes equipment for cooking, pressing, and drying, as well as ancillary equipment for handling and processing the raw materials and finished products.

How Fishmeal Processing Improves Capacity and Efficiency

The production line typically includes equipment for cooking, pressing, and drying, as well as ancillary equipment for handling and processing the raw materials and finished products.

In order to manage the waste gas produced, a fish meal plant production can install a waste gas treatment system. This system typically comprises a cyclone dust collector, a bag filter, and a scrubber.