Operating a fishmeal plant often comes with a significant challenge: unpleasant and potentially harmful odors. These emissions—typically composed of ammonia, hydrogen sulfide, and amines—can lead to regulatory fines, community complaints, and reduced worker comfort. Therefore, knowing how to reduce odor in a fishmeal plant is not just about compliance but also about maintaining your reputation and operational efficiency.

Why Odor Control Is Essential in Fishmeal Processing

Fishmeal production involves high-temperature processes such as cooking, pressing, drying, and evaporating protein water. These steps can emit strong and persistent odors if not properly managed. As environmental regulations tighten globally, fishmeal plant operators must adopt effective solutions to minimize odor emissions.

Effective Methods to Reduce Odor in Fishmeal Plants

-

Install a Biofilter System

Biofilters use microorganisms to degrade odorous compounds biologically. This is a highly effective and eco-friendly method of removing VOCs and sulfur-based gases. -

Use Wet Scrubbers

Wet scrubbers capture odor-causing particles by passing exhaust gas through a liquid, usually water or a chemical solution, which neutralizes the gases. -

Condensation and Heat Recovery Units

By condensing steam and recovering heat from exhaust air, you can remove significant amounts of odor-laden moisture from the air stream. -

Proper Enclosure and Ventilation Design

Ensuring all processing steps are enclosed and well-ventilated helps prevent uncontrolled odor leakage. -

Protein Water Evaporation Control

Concentrating and treating stickwater (protein water) before discharge significantly reduces the potential for odor generation.

Our Advantage in Odor Control Solutions for Fishmeal Plants

As a professional fishmeal plant equipment manufacturer, our company offers complete and customizable odor control systems designed to meet both environmental regulations and production needs. Here’s why customers in over 30 countries trust us:

-

✅ Integrated Systems: We supply turnkey odor control solutions, including biofilters, wet scrubbers, condensers, and protein water evaporators.

-

✅ Proven Designs: Our equipment is installed in operating plants with proven odor reduction performance exceeding 95%.

-

✅ Custom Engineering: Each system is designed based on airflow, raw material, plant layout, and local emission standards.

-

✅ Energy Efficiency: Our systems are optimized to reduce both emissions and energy consumption.

Conclusion

Reducing odor in a fishmeal plant is not only essential for environmental compliance but also for maintaining a safe and productive working environment. Whether you’re operating a small-scale fishmeal facility or a large industrial processing line, implementing the right odor control systems is key.

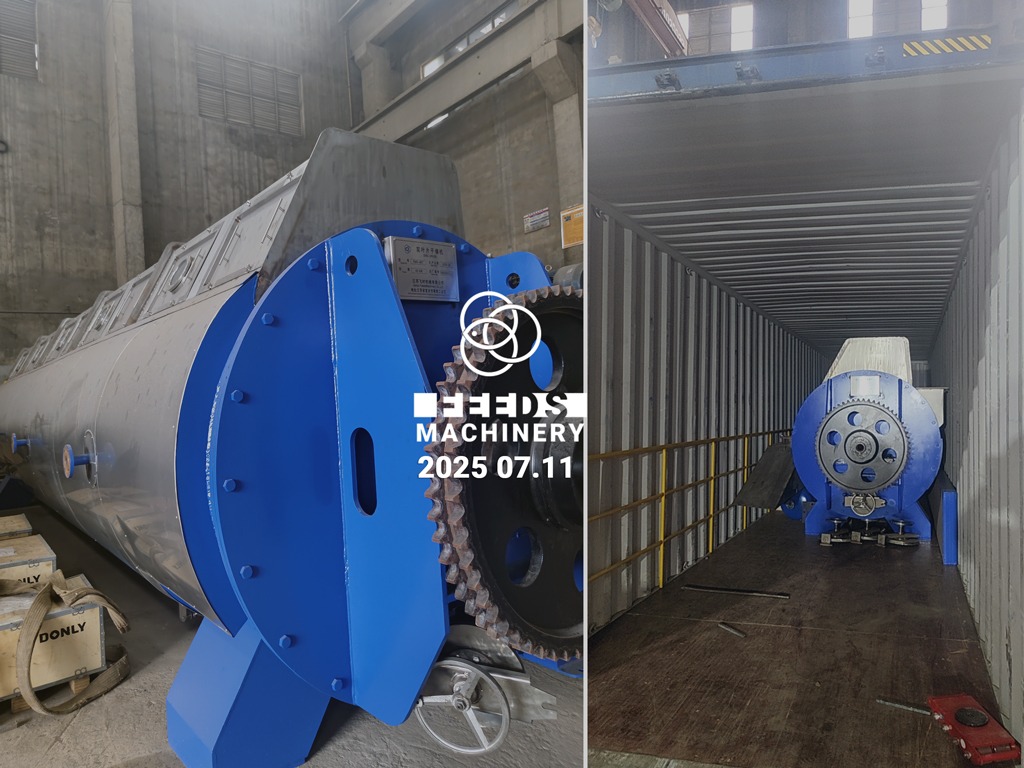

At FEEDSMACHINERY, we help fishmeal producers build smarter and cleaner facilities. Contact us today to learn more about our odor reduction solutions and get a tailored quote for your fishmeal plant.