As global demand for animal feed continues to rise, fish meal production plays an essential role in the supply chain. However, operating a fish meal plant can pose environmental challenges, including odor emissions, wastewater discharge, and energy consumption. To stay compliant with environmental regulations and support long-term sustainability, manufacturers must implement eco-friendly technologies and best practices.

In this article, we explore how to effectively reduce the environmental impact of fish meal plants while maintaining production efficiency—and how our company provides customized solutions to help you achieve those goals.

Common Environmental Challenges in Fish Meal Plants

Fish meal processing involves cooking, pressing, drying, and grinding raw fish materials. This process generates several environmental issues, including:

-

Odorous gases such as ammonia and hydrogen sulfide

-

Protein-rich wastewater, often called “stickwater”

-

Energy-intensive operations from steam dryers and cookers

-

Solid waste residues from raw material handling

If not properly managed, these factors can affect nearby communities and lead to non-compliance with environmental standards.

Sustainable Solutions for Fish Meal Processing

To minimize these impacts, modern fish meal plants are adopting a combination of technical upgrades and smarter system designs. Here are some proven strategies:

1. Install Odor Control Systems

Using biofilters, wet scrubbers, and condensers, plants can effectively treat waste gases. Our odor control units are specially designed to capture and neutralize volatile compounds before release.

2. Recover and Concentrate Stickwater

Rather than discharging wastewater, invest in protein water concentration systems (like evaporators or ceramic membrane filters) to reclaim valuable protein and reduce pollution.

3. Optimize Energy Usage

Switching to steam dryers with energy recovery units can significantly cut down fuel consumption. Our equipment includes options for thermal insulation and heat recovery, enhancing energy efficiency.

4. Use High-Efficiency Machinery

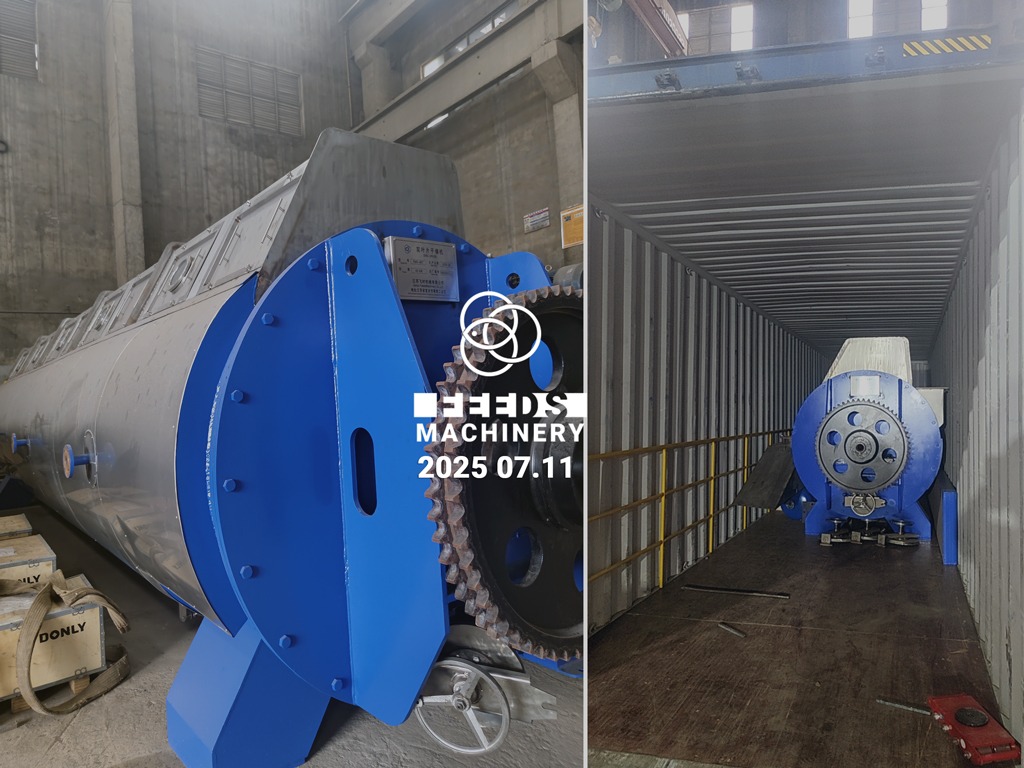

Modern fish meal plant equipment, including cookers, press machines, and dryers, are engineered for higher output with lower emissions. Our systems are modular, easy to integrate, and built for durability.

5. Ensure Proper Waste Management

Solids, sludges, and other residues can be processed into value-added products like fertilizer or animal feed additives, further reducing waste.

Why Choose Our Company for Sustainable Fish Meal Solutions

With over a decade of experience in fish meal processing technology, our company is committed to helping clients reduce their environmental footprint. We offer:

-

✅ Turnkey fish meal plant solutions with integrated pollution control

-

✅ Customized designs to meet local environmental standards

-

✅ High-performance odor treatment and wastewater concentration systems

-

✅ Ongoing technical support and maintenance service

-

✅ Competitive pricing for international markets

We have successfully delivered solutions to clients across Africa, Southeast Asia, South America, and the Middle East.

Conclusion

Reducing the environmental impact of a fish meal plant is no longer optional—it’s essential for regulatory compliance, community acceptance, and sustainable business growth. By upgrading to advanced processing and treatment technologies, you can protect the environment while boosting profitability.

If you’re looking for a reliable partner in sustainable fish meal production, contact us today. Our expert team is ready to design and deliver the best solution for your needs.