Complete Fish Meal Production Line for Efficient and Sustainable Processing

UN fish meal production line is an essential system in the marine and animal feed industries. It transforms raw fish or fish by-products into high-protein fish meal through a series of mechanical and thermal processes. This ingredient is widely used in aquaculture, livestock feed, and pet food industries due to its high nutritional value.

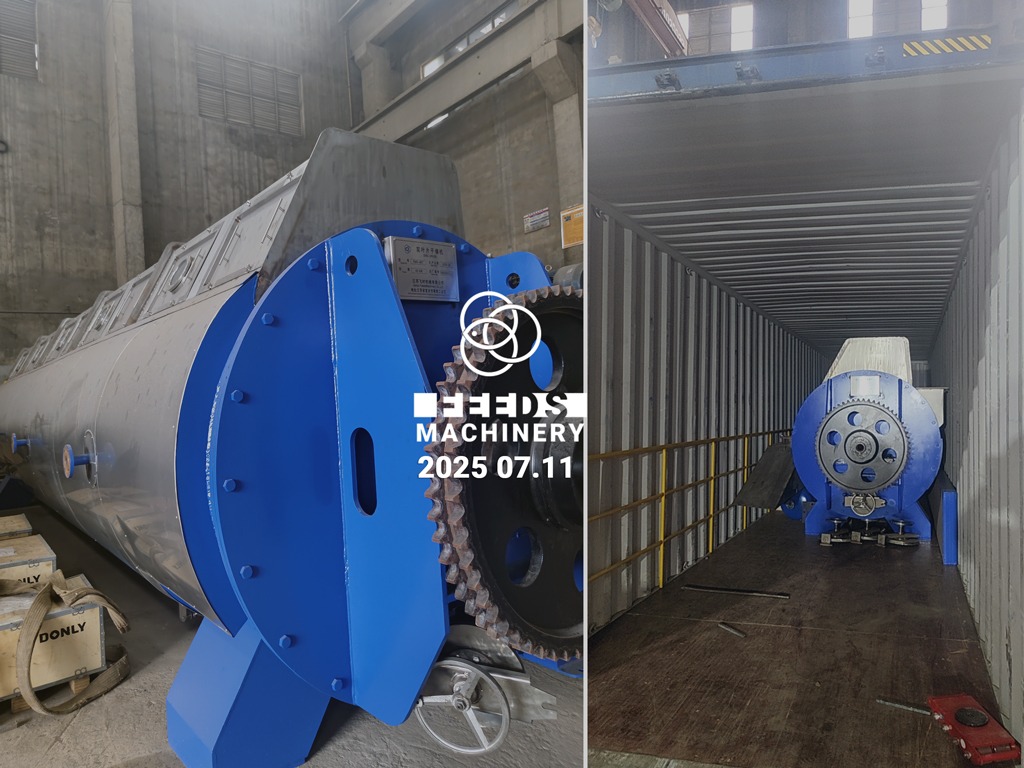

At our company, we specialize in designing and manufacturing customized fish meal production lines that combine efficiency, durability, and environmental protection. Whether you’re setting up a new facility or upgrading an existing one, our engineering team provides end-to-end solutions tailored to your specific needs.

What Is a Fish Meal Production Line?

A fish meal production line typically includes several core units:

Raw material receiving and storage system

Fish meal dryer (steam or indirect drying)

Milling system

Odor control unit (biofilter or wet scrubber)

Protein water evaporation and concentration system

These components work together to reduce moisture, sterilize, separate liquids and solids, and ultimately produce high-quality fish meal and fish oil.

Key Features of Our Fish Meal Production Line

High Processing Efficiency

Our systems are designed for continuous operation, minimizing downtime and increasing yield.Modular Design

Each component of the fish meal plant can be customized or expanded based on production needs—from 1 ton/hour to 100 tons/day.Effective Odor Control

We provide complete odor treatment solutions using biofilters, wet scrubbers, and condensers to meet environmental standards.Energy Optimization

Our fish meal dryers and evaporators are engineered for energy recovery and heat reuse, reducing operational costs.Corrosion-Resistant Materials

All contact surfaces use stainless steel or anti-corrosive coatings to ensure durability and hygiene.

Applications of Fish Meal Production Line

Marine fish meal processing

Poultry by-product rendering

Aquaculture feed production

Waste reduction in seafood processing plants

Whether you process whole fish, fish heads, or offal, our production lines are equipped to handle a wide range of raw materials with consistent output quality.

Why Choose Us as Your Fish Meal Production Line Supplier

Our company stands out among fish meal plant equipment manufacturers thanks to:

✅ Over 15 years of experience in the fish meal industry

✅ Successful installations in over 30 countries

✅ Strong R&D capabilities for customized layouts

✅ On-site technical support and training

✅ Competitive pricing and fast delivery

We are not just a supplier—we are your long-term partner in efficient fishmeal processing.

Conclusion

If you are planning to build or upgrade a fish meal production line, choosing the right equipment and partner is critical to your success. Our tailored solutions deliver high efficiency, meet environmental regulations, and ensure long-term profitability.

Contact us today to get a free layout design and quotation for your fishmeal production project. Let’s build a smarter and more sustainable fish meal plant together.