Introduction

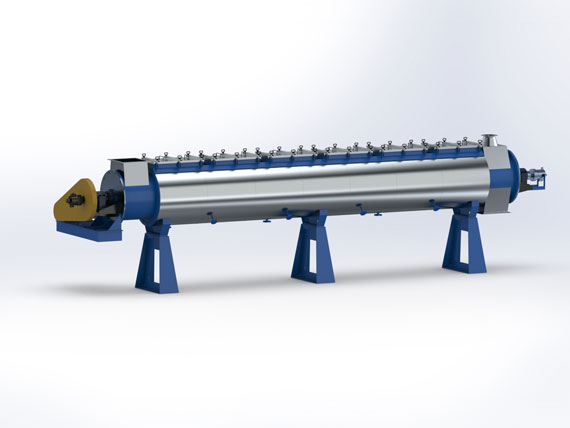

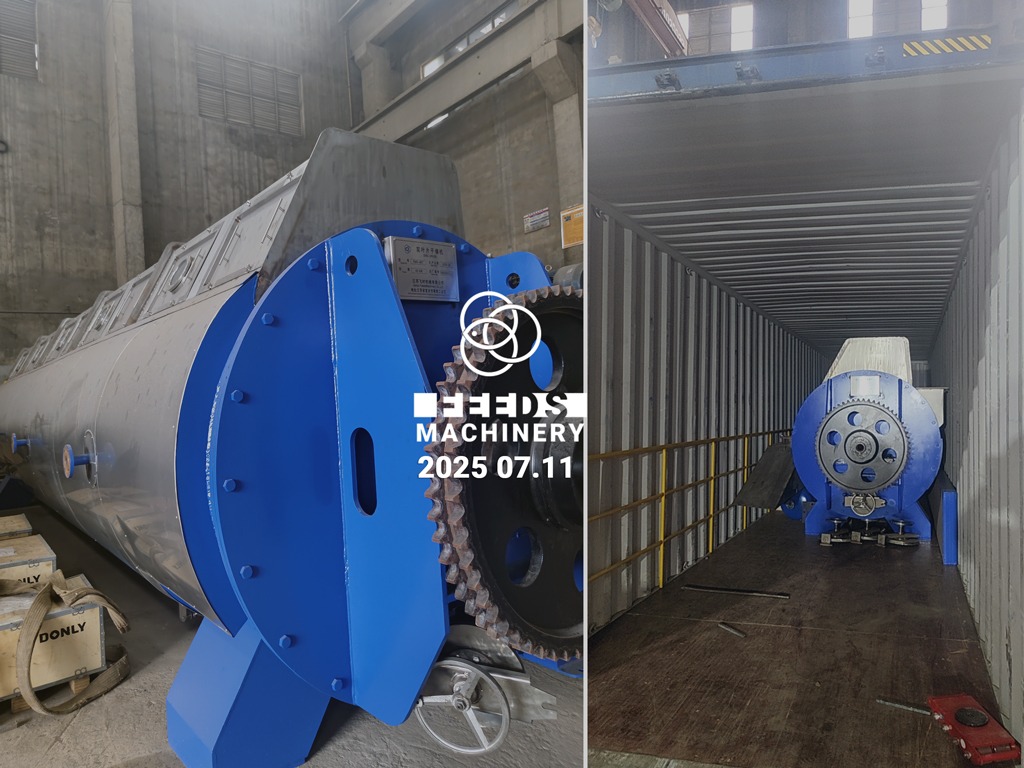

The fish meal cooker uses saturated steam as the heat source to indirectly heat the material through the hollow blade spiral main shaft and interlayer. It is also equipped with several direct injections to speed up the cooking process or handle larger raw material pieces.

Cooking aims to rupture the fat cells in the fish body, coagulate the protein, and fully extract the oil and water from the fish body to prepare for subsequent pressing. Typically, the machine operates by cooking raw materials at a temperature of 95°-100°C for 15-20 minutes.

Application

The fish meal cooking machine cooks fish, seafood, and other marine animals by heating them, and turns them into fish cakes that are easy to press. Then, the fish cakes undergo pressing, drying, and other processes to produce fish meal.

Related Posts

Related Products

We can offer customized fish meal processing solutions, including production lines, drying equipment, and oil separation.